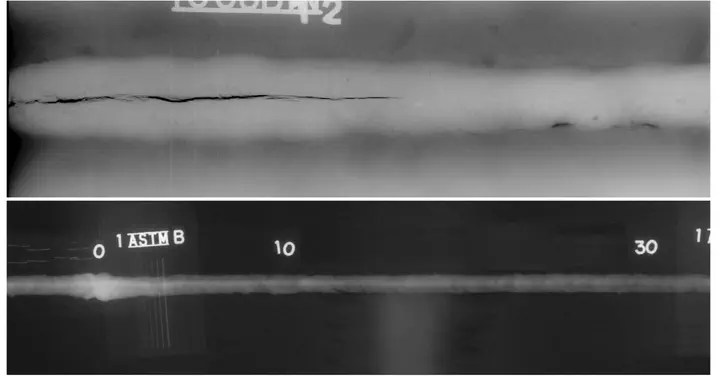

Defect detection and classification in welding using deep learning and digital radiography

Abstract

Continuous and digitized monitoring and automated inspection are key parts of modern manufacturing and sustainment of aging infrastructure. The growing demand for these needs and shortage of required skill sets can slow down the global economy by increasing the risk or costs associated with catastrophic events. The diversity of requirements and specialized standards and codes around the world, along with the time-sensitive aspect of such inspections, makes automated fault detection and classification a prime application for utilizing artificial intelligence as an assistive tool that not only automates repeated tasks but also provides users with supporting inference to increase confidence before and during the inspection operation. In most critical cases, non-destructive testing (NDT) must be done once immediately after the weld is created and then on a scheduled or unscheduled repeated basis as the weld …